Founded in 1978 in the San Francisco Bay Area, the company originally known as Orthopaedic Systems Inc. (OSI) became part of the Japan-based Mizuho Corporation in 2002. Mizuho OSI has since grown into a market leader in surgical tables. With a focus on innovation and improving surgical outcomes, the manufacturer is known today for its advanced medical technology and specialty surgical solutions.

What is true for its products also holds true for Mizuho OSI’s internal processes. Striving for operational efficiency, Mizuho OSI sought to modernize its processes. To leverage SAP’s low-code capabilities, the company worked with SAP AppHaus in 2024. Together, they began exploring automation opportunities using SAP Build Process Automation and SAP Build Work Zone. During an initial SAP Business Technology Platform (SAP BTP) explore workshop, Mizuho OSI’s IT and business teams took a closer look at the manual fixed asset creation process.

Use case: Approving and creating new fixed assets

The workshop uncovered key inefficiencies in the manual purchase acquisition process, particularly its e-mail-driven workflow involving requesters, approvers, and finance accountants. This approach not only introduced a high risk of errors but also slowed down the process significantly. For high-value fixed asset purchases, the need for additional approvers and supporting details further extended the procurement cycle, highlighting the necessity for a more streamlined and automated solution.

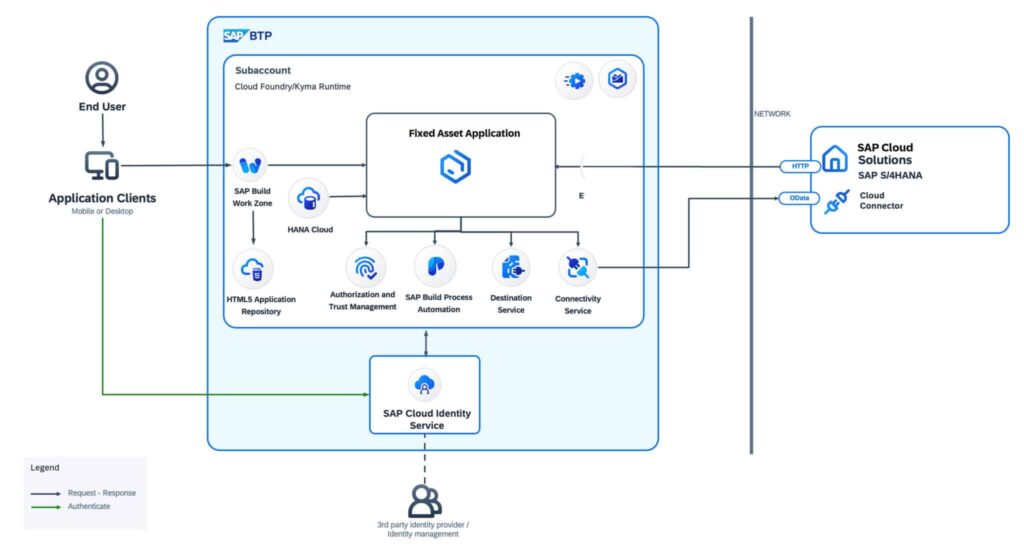

With guidance from SAP experts, the joint project team designed a streamlined, automated process for fixed asset approval and creation. Leveraging SAP Build Process Automation and SAP Build Work Zone, Mizuho OSI’s in-house IT team successfully developed and deployed a solution using a low-code application framework, accelerating implementation while reducing complexity.

As we grow from a mid-sized to a large enterprise, tools like SAP Build Process Automation are essential—not only for driving process efficiency but also for extending the reach of our lean IT team. We’re grateful to SAP AppHaus and the SAP product team for their guidance throughout the journey—from identifying the right use case to providing the technical support needed to bring this proof of concept into production. The new automated process is a major improvement over our previous manual approach. I couldn’t be happier with the results!

– Lindsay Neill, Director of Enterprise Application at Mizuho OSI

Measured results

After testing and implementing this new solution, both end users and the project team could measure a reduction in manual effort and observe improved process efficiencies, such as:

– 40% increase in process efficiency from days of pending response to automatic processing

– 65% reduction in approval time since asset costs below a certain threshold can be automatically processed

– 70% decrease in manual efforts, with fewer errors and faster decision-making since human intervention is now only required for exceptions

It’s been a true pleasure collaborating with the team at Mizuho OSI. Their forward-thinking mindset and readiness to challenge the status quo made this collaboration exceptional. I’m proud of what we achieved together using SAP BTP and SAP Build solutions and even more excited to see how this success inspires and empowers them to take on future projects with confidence and momentum.

– Tina Tuan, Senior Director at SAP AppHaus Palo Alto

Through close collaboration between SAP and Mizuho OSI, this project has proven that roadblocks can be overcome with the right partnership. The team successfully implemented an innovative solution for fixed asset approvals, laying a strong foundation for future initiatives leveraging SAP Build solutions and SAP Business Technology Platform. On the horizon is a promising next milestone, somewhat broader in scope, such as material master automation.

One thing is certain, the Mizuho OSI project team is driven by the company’s powerful mindset: Dare to go further. Care to do more

Article originally published by SAP News Center.